In previous blog installments we discussed how our car had the incorrect fuse panel fitted to it at some time in its life. As such we needed to source, restore, and (when unavailable) manufacture the missing components needed to replicate a new one. Some of the posts on this subject are here:

http://dino246blog.blogspot.ca/2011/12/little-help-from-sweeden-fuse-panel-is.html

http://dino246blog.blogspot.ca/2013/05/121-gigawatts-finishing-fuse-panel.html

http://dino246blog.blogspot.ca/2013/01/a-faint-rectangle-helps-dino-restorers.html

http://dino246blog.blogspot.ca/2013/12/original-vs-replacement-difference-in.html

With the fuse panel completed it was now on to the daunting task of restoring our wiring harness. In most instances the fastest and easiest route would be to buy a replacement harness however, in our case, certain nice original details of our harness allowed us to justify the massive extra work involved in restoring rather than replacing:

- Our original harness was still supple and the plastic on the wires had not dried out with time

- Despite 3 colour changes over the decades our harness had no paint overspray on it which is almost impossible to properly remove.

- The original harness has markings in Italian on them denoting the task of the individual wires. This in addition to wire colours that are not replicated with the reproduction harness' made keeping the original an easier decision.

- Reproduction wiring harnesses have different wire ends to original making them an immediate giveaway to the knowledgeable observer

With the decision to restore the process all started with getting the old and dirty wiring harness out of storage.

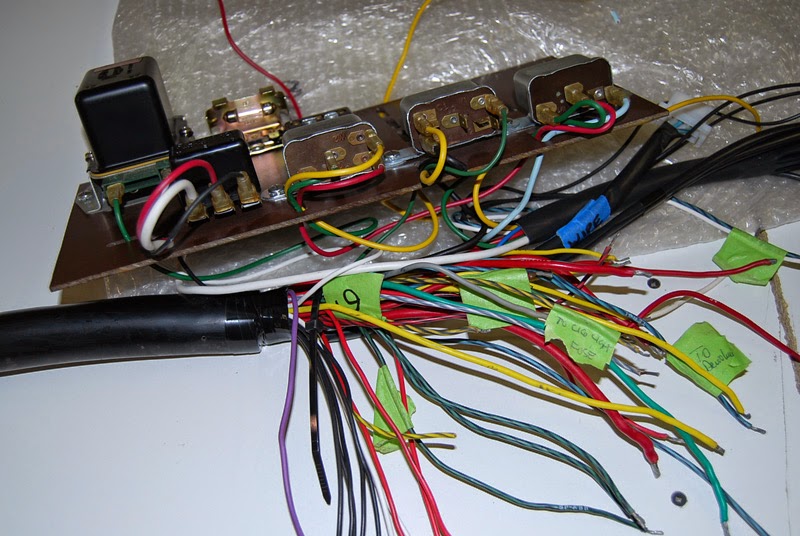

The next step was to lay everything out on a LONG table where the entire harness would be compared to period photos and the original wiring diagrams to ensure that everything is correct. Despite the few circuits involved this job took many days of concentrated effort to get right.

By this stage the harness has most of its cables identified. Once this is done each cable is tested for continuity and resistance to make sure that there are no unexpected problems. Inevitably a few bad wires are found and they are carefully removed whole and replaced. Where we got very lucky is that all of the bad wires were easy to replace colours rather than some of the more strange striped wires that the harness has for some of its circuits.

With the harness all mapped out the next step is full on restoration which we will cover in our next post. Stay tuned.

I read your blog. Very good and useful information about Wire Harness Manufacturers.Thanks for sharing

ReplyDeleteSee my blog also

Wiring Harness Manufacturers

Appreciating the time and effort you putt into your blog and in depth information you present.Thanks for that list.

ReplyDeleteToroidal Transformer in India

Thanks for sharing nice information about how wires are tested and how therebsolve the problems in wire harness manufacturing. Great Post!

ReplyDeleteWire assembly manufacturers in India | Cable Harness Manufacturers in India

Great Post! Awesome information you shared about how harness manufactures solve the problems of wires and cables. Thanks for sharing.

ReplyDeleteAerospace wiring harness manufacturer in India | Aerospace cable harness manufacturer in India

Nice Post! Good information you shared about how there are solve the problems of wires and cables at harness manufacturing. Keep sharing.

ReplyDeleteWire assembly manufacturers in India | Cable Harness Manufacturers in India

Great Blog! Nice information about wires and cables problem solving problems in harness manufacturing. It is so helpful to me. Thanks for sharing.

ReplyDeleteWire Harness Manufacturer in India | Wire Assembly Manufacturers in India

Nice blog! Thanks for Sharing such a valuable information.Keep posting.

ReplyDeleteWire Harness Manufacturer in India | Wire Assembly Manufacturers in India

Aerospace Cable Harness Manufacturer in India | Cable Harness Manufacturers in India

Very good and useful information about Wire Harness Manufacturers.Thanks for sharing.

ReplyDeleteWire Harness Manufacturer in Germany | Wire Assembly Manufacturers in Germany

Thanks for sharing nice information about how wires are tested in wire harness manufacturing.

ReplyDeleteWire Harness Manufacturer in India | Wire Assembly Manufacturers in India

Nice post and Awesome information you shared about wiring harness.Thanks for sharing.

ReplyDeleteAerospace wiring harness manufacturer in India | Air core inductor manufacturers in India

Vary nice post and informative too. keep posting.

ReplyDeleteAerospace Cable Harness Manufacturer in India | Cable Harness Manufacturers in India

Thank you for sharing such good blog. good information.

ReplyDeleteAerospace Cable Harness Manufacturer in India | Cable Harness Manufacturers in India

Good to see such a nice blog posts Contract Manufacturers

ReplyDeleteThis is a great blog! Thanks for the information's. I always enjoy reading your blogs! Top Wire Company In India.

ReplyDeleteAmazing post. Thank You for sharing such useful information about wiring harness manufacturer . Keep posting.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteWow, this is good post, I have also seen this information here, electronic distributor

ReplyDeleteThe wire cable is tested perfectly but how can we test resistance on high voltage of power this should be explained in your next post, an thank for sharing the informative blog on how Custom Cable Manufacturers will test the cable!!

ReplyDeleteNice Blog. Thanks for sharing the informative blog of Best Wire Harness Manufactures in India

ReplyDeleteNice information on wire harness

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThanks for sharing nice information about how custom cable Manufactures are tested .custom cable Manufactures

ReplyDeleteNice article. thanks for sharing i hope you can post article about using electrical wire brand

ReplyDeleteThanks for sharing the valuable blog on Best Custom Cable Manufacturers in USA

ReplyDeleteThe first part of the wiring harness restoration series is fascinating! It's great to see detailed insights into the restoration process. Looking forward to the next parts to learn more about techniques and tips for restoring wiring harnesses effectively.

ReplyDeleteRestoring our car's wiring harness has been a challenging but rewarding journey. Unlike opting for a replacement, we decided to keep the original harness due to its unique qualities. It's still supple, has no paint overspray, and features Italian markings and original wire colors that aren't replicated in reproductions. If you're looking for wholesale electrical wire for similar projects, it's worth considering the benefits of restoration over replacement.

ReplyDeleteAmazing post. Thank You for sharing such useful information about Best wire harness manufacturers in India . Keep posting.

ReplyDeleteWonderful blog on , Best Wire Harness Manufacturers in Indiathanks for sharing.

ReplyDeleteThe demand for reliable cable solutions is rising, and custom cable manufacturers in the USA are meeting that need efficiently.

ReplyDeleteBest Custom Cable Manufacturers in USA

Very informative post on how custom cables improve performance across industrial applications.

ReplyDeleteBest Custom Cable Manufacturers in USA.

Impressive insights! Violin Technologies seems to be setting high standards in the field of precision machined components in the USA. The commitment to quality, tight tolerances, and customized manufacturing solutions is exactly what industries need today for dependable and efficient operations. Looking forward to seeing more innovations from your team! Precision Machined Components in USA

ReplyDeleteReally enjoyed this detailed look into the long table wiring harness project—your precision and documentation are impressive. Projects like this highlight why custom cable manufacturers in USA focus so heavily on tailored design, accuracy, and quality control to meet unique build requirements. Looking forward to more of your restoration updates!

ReplyDeleteThis highlights how innovation is shaping the future of cable technology.

ReplyDeleteBest Wire harness manufacturers in USA

Really helpful article! Finding the Best Wire harness manufacturers in USA can be challenging, especially when looking for companies that combine quality materials, precision engineering, and reliable customer support. It’s always good to connect with suppliers who understand both custom and large-scale production needs.

ReplyDeleteReally enjoyed reading about the wiring harness restoration! It’s amazing how much detail goes into bringing old components back to life. Using the right automotive electrical wire makes such a difference in performance and safety especially for vintage cars where precision matters.

ReplyDeleteImpressive deep-dive into restoring an original long wiring harness with patience and attention to detail — a great read for classic car enthusiasts!

ReplyDeleteBentec Components & Trading Pte Ltd