The time has come to restore the horn on the Dino. In Italy the horn rivals the engine for importance on a car and they are always sure to fit something special. 01464 had its horn replaced for a plastic German Bosch unit at some time and this just would not do. An original Italian Fiamm metal trumpet horn was sourced out (compressor from the wrecked Lamborghini previously featured and horn from eBay) and, as always, an extensive restoration was carried out to bring it back to perfect condition.

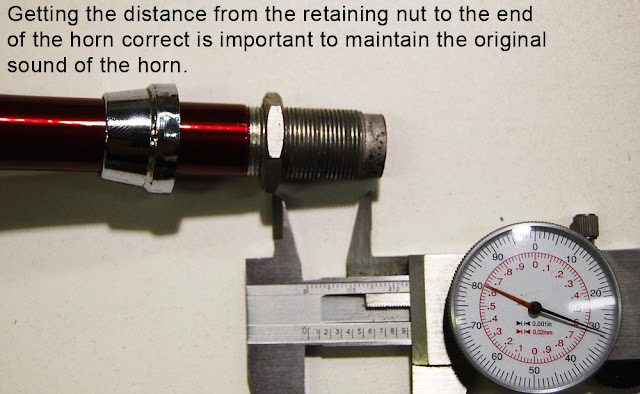

These horns came in two colours, light blue and candy apple red. Dino's were fitted with red horns and the preparation to paint them turned out to be an exhaustive and time consuming task. After many hours of surface polishing and 2 attempts to powder coat, we are pleased to announce that they turned out perfect with a glass-like finish. Later, all the other components were restored, re-assembled, and tested.

Dino has re-gained his original voice.

Now for some pictures. First up is a great period photo of the Fiamm assembly line in Mantova Italy; home town of the great Italian racing driver Tazio Nuvolari. The model shown in the photo is a bit different to the correct Dino model but the picture was too good to pass up.

Sunday, August 14, 2011

Thursday, August 11, 2011

Things get hot. The heater core restoration

The heater core and related housing assembly, like most other parts on the car, was in need of a good going over. The case was media blasted and powder coated to the correct semi-gloss finish. The heater core was disassembled, cleaned, re-soldered, and painted to the correct iron oxide colour. Lastly all of the hardware was re-plated and the entire assembly was put back together. Joined to it are the restored brake reservoir bottles and heater core valve (both subjects of previous blog posts).

The completed assembly is now ready to re-install. As always we'll begin with some before photos.

The completed assembly is now ready to re-install. As always we'll begin with some before photos.

Monday, August 8, 2011

Fuel tank finishing. Where doing a sloppy job is required

With the fuel tanks straightened of all of their dents and pressure tested, it was time to apply the finish coat to their aluminum skin. Originally these tanks had a thick and sloppy tan coloured coating on them. Luckily we found that Wurth makes a product that is an exact match to original.

Before anything the tanks were sprayed with a thin coat of zinc chromate primer and then several coats of the Wurth undercoating. Normally we go to great lengths to make any finish we apply as smooth as possible but in this instance, for a truly authentic finish, a thick and lumpy coat was the order of the day.

Paul seemed to revel in the task as for one fleeting moment he got to butcher a paint job. The results as always from him are perfect.

Before anything the tanks were sprayed with a thin coat of zinc chromate primer and then several coats of the Wurth undercoating. Normally we go to great lengths to make any finish we apply as smooth as possible but in this instance, for a truly authentic finish, a thick and lumpy coat was the order of the day.

Paul seemed to revel in the task as for one fleeting moment he got to butcher a paint job. The results as always from him are perfect.

Sunday, August 7, 2011

Going backwards to move forwards

With no confidence in the quality of the previous bodywork attempt, everything was stripped off and work is starting from scratch. In a way this was good as all of the negative energy that surrounded the past few months is gone and we can concentrate on a fresh beginning.

The body is now in a fresh coat of metal prep with metal work beginning in earnest this week.

The body is now in a fresh coat of metal prep with metal work beginning in earnest this week.

Subscribe to:

Posts (Atom)