One of the problems many Dino owners struggle with is properly bonding the metal catches on the front vent windows. Knowing this to be a problem we investigated a number of adhesives that would offer a reliable bond. Sticking metal to glass is never something that is easy and on the vent windows things are further complicated as the glue join is under quite a bit of tension from the spring effects of the molding rubber that surrounds the vent window. In the end the solution came from our neighbor Joe who offered us a high strength adhesive made by Loctite and cured using the invisible powers of UV light. He supplied us with the glue, curing lamp, and requisite yellow safety glasses (that make our Dino disappear)

Before trusting the glue on the car we ran a test using a scrap piece of glass and an extra mount we had. The cool thing about the adhesive is that it cures in about 90 seconds.

Once dry we administered the most un-sophisticated durability test we could muster. With the glass held in a vise we hammered and hammered until the bond or the glass broke. In the end neither failed as we just could not grip the thick piece of glass we had tight enough to keep it from moving however with the metal mount deforming and starting to bend we were pretty sure we had the glue for the job.

Now for the real thing. We carefully located the mount on the vent window using a black piece of decal material with a perfect hole cut in it. The decal served 2 purposes. One is that it really helped locate the pin well and second because no light goes through it, all of the overflow glue stays fully liquid making for a perfect masking. When the light is turned off all you need to do is pull the decal away and there is no mess or leakage to clean up. To be honest we tripped over the second benefit totally by accident but it was very welcome and a tip worth sharing.

Lastly here is the finished assembly. Ignoring that everything is covered in fingerprints and could use a proper cleaning, another job is removed off of the list :)

Monday, May 26, 2014

Saturday, May 24, 2014

Path of least resistance: Wiring harness restoration Part 3

In the last few posts we have been reviewing the wiring harness restoration. The harness is now finished and ready to go in.

The first step to getting the harness in is establishing its general path into the car and then preparing it for fitting. In the photo below Paul looks eager to get to work and to speed things along we put the bulk of the harness on a rolling cart. It of course goes without saying that we covered the paint very carefully to avoid any damage.

On the Dino the bulk of the harness enters on the drivers side just under the windshield wiper motor

Below you can see the wires once they passed through the front bulkhead and are now ready to feed through the car.

Some of the wires stay in the passenger cabin while others pass along just under the surface of the dashboard.

While most of the wires are concentrated in the front half of the car there are still some wires that need to go to the back to run the ignition, tail lights, and other electrical items. These wires exit the under dash area on the passenger side, run down the front wheel arch and along the main side chassis tube back to the rear of the car. In order to keep these wires clean and to help feed them quickly we wrapped them in plastic. This make quick work of fitting the harness.

In the end while we have lamented about some terrible jobs on this car, however with the task being done early in the build, the wiring installation went rather smoothly. Rough running of the wires tool about 30 minutes while final positioning and checking well lets say took rather more time.

Wednesday, May 21, 2014

Wires wires everywhere: Wiring harness restoration Part 2

In our last post we introduced our task of restoring the original wiring harness. As noted the first step was to map out the entire harness tracing each individual wire to its corresponding circuit. With this job done we could now turn our attention to the actual restoration of the harness which can be broken down in 4 separate steps:

1. Remove and restore all the wire terminal insulators

2. Replace all plastic sheathing on wires and add new wire ends

3. Attach harness to fuse panel

4. Test the assembly

Now we shall cover the various steps:

1. Remove and restore all the wire terminal insulators

One part that is not available anywhere are replacements for the original wire ends. Molded in soft clear plastic they carry the word ITALY on them and are a nice original detail. We were lucky to have ours in pretty nice shape and after a few hours of cleaning and scrubbing got them to the point where they were looking quite good.

2. Replace all plastic sheathing on wires and add new wire ends

This one was the big one. The entire harness is covered with a black plastic sheathing to protect the wires from abrasion. Over time this material hardens and looses its flexibility. The big challenge comes in looking at the harness as a whole and figuring out the order to replace the sheathing as the whole assembly is like a big jigsaw puzzle with no instructions. Generally you work from larger diameter to smaller but the harness can get pretty complicated and I found the only solution was to break the harness down into smaller sections. Each section was then identified, photographed, and then drawn on a piece of paper with notes showing the location of breaks and electrical tape.

Because each section feeds into the next the photos and drawings become critical because ALL of the sheathing on the entire harness needs to be removed in order to be able to replace it. No matter how good your memory is, over the several days this job takes, the reference drawings are essential to getting things right.

1. Remove and restore all the wire terminal insulators

2. Replace all plastic sheathing on wires and add new wire ends

3. Attach harness to fuse panel

4. Test the assembly

Now we shall cover the various steps:

1. Remove and restore all the wire terminal insulators

One part that is not available anywhere are replacements for the original wire ends. Molded in soft clear plastic they carry the word ITALY on them and are a nice original detail. We were lucky to have ours in pretty nice shape and after a few hours of cleaning and scrubbing got them to the point where they were looking quite good.

2. Replace all plastic sheathing on wires and add new wire ends

This one was the big one. The entire harness is covered with a black plastic sheathing to protect the wires from abrasion. Over time this material hardens and looses its flexibility. The big challenge comes in looking at the harness as a whole and figuring out the order to replace the sheathing as the whole assembly is like a big jigsaw puzzle with no instructions. Generally you work from larger diameter to smaller but the harness can get pretty complicated and I found the only solution was to break the harness down into smaller sections. Each section was then identified, photographed, and then drawn on a piece of paper with notes showing the location of breaks and electrical tape.

Because each section feeds into the next the photos and drawings become critical because ALL of the sheathing on the entire harness needs to be removed in order to be able to replace it. No matter how good your memory is, over the several days this job takes, the reference drawings are essential to getting things right.

With all of the wire re-covered it is now time to put new wire ends on. Originally the wire ends from Ferrari were tinned and have a silver colour (reproduction harnesses are generally gold in colour). We sourced the correct wire ends and bought the right crimping tool to perfectly match the original crimps. This matched to the restored plastic ends gave us wires that looked factory fresh.

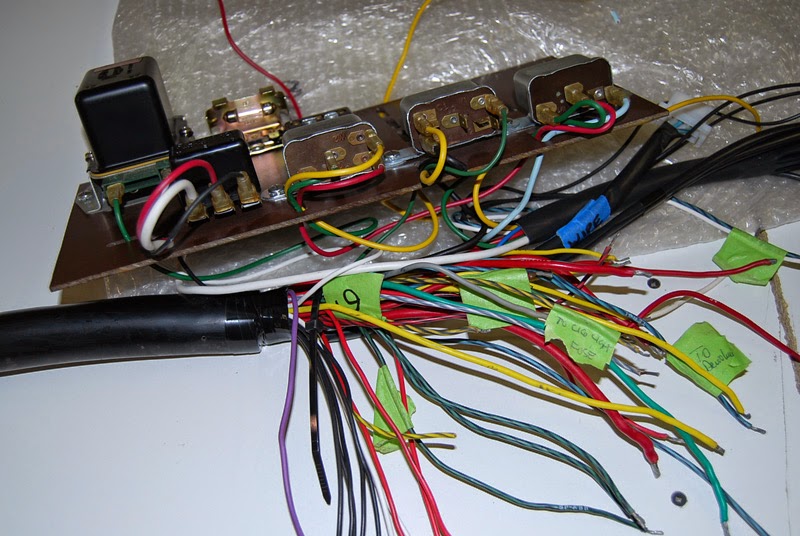

3. Attach harness to fuse panel

As previously reported our fuse panel had been replaced leaving us to make a new one from scratch. As such we had no data on which to figure out the connections to the panel. This easily ate up 10 times the work as it should have because simple connections turned into elaborate testing procedures before running power to the panel. In the end though we were really pleased that everything turned out well.

4. Test the assembly

Despite all the time we spent trying to get things perfect you never know until you test the assembly. Invariably something goes wrong and when things got sticky for us our friend Myron S. came by the shop to help us along. Myron is a professional electrical engineer and his input was invaluable to getting our electrics working well. We owe him a debt of gratitude for taking time out of his Saturday to come and help us out.

In all the electrical harness took over 2.5 weeks of solid work to get right. It was much more involved than I ever imagined but the result is a 40 year old assembly that looks like it was made yesterday. Our next installment shows the harness going in.

Monday, May 19, 2014

The long table: Wiring harness restoration Part 1

In previous blog installments we discussed how our car had the incorrect fuse panel fitted to it at some time in its life. As such we needed to source, restore, and (when unavailable) manufacture the missing components needed to replicate a new one. Some of the posts on this subject are here:

http://dino246blog.blogspot.ca/2011/12/little-help-from-sweeden-fuse-panel-is.html

http://dino246blog.blogspot.ca/2013/05/121-gigawatts-finishing-fuse-panel.html

http://dino246blog.blogspot.ca/2013/01/a-faint-rectangle-helps-dino-restorers.html

http://dino246blog.blogspot.ca/2013/12/original-vs-replacement-difference-in.html

With the fuse panel completed it was now on to the daunting task of restoring our wiring harness. In most instances the fastest and easiest route would be to buy a replacement harness however, in our case, certain nice original details of our harness allowed us to justify the massive extra work involved in restoring rather than replacing:

- Our original harness was still supple and the plastic on the wires had not dried out with time

- Despite 3 colour changes over the decades our harness had no paint overspray on it which is almost impossible to properly remove.

- The original harness has markings in Italian on them denoting the task of the individual wires. This in addition to wire colours that are not replicated with the reproduction harness' made keeping the original an easier decision.

- Reproduction wiring harnesses have different wire ends to original making them an immediate giveaway to the knowledgeable observer

With the decision to restore the process all started with getting the old and dirty wiring harness out of storage.

The next step was to lay everything out on a LONG table where the entire harness would be compared to period photos and the original wiring diagrams to ensure that everything is correct. Despite the few circuits involved this job took many days of concentrated effort to get right.

By this stage the harness has most of its cables identified. Once this is done each cable is tested for continuity and resistance to make sure that there are no unexpected problems. Inevitably a few bad wires are found and they are carefully removed whole and replaced. Where we got very lucky is that all of the bad wires were easy to replace colours rather than some of the more strange striped wires that the harness has for some of its circuits.

With the harness all mapped out the next step is full on restoration which we will cover in our next post. Stay tuned.

http://dino246blog.blogspot.ca/2011/12/little-help-from-sweeden-fuse-panel-is.html

http://dino246blog.blogspot.ca/2013/05/121-gigawatts-finishing-fuse-panel.html

http://dino246blog.blogspot.ca/2013/01/a-faint-rectangle-helps-dino-restorers.html

http://dino246blog.blogspot.ca/2013/12/original-vs-replacement-difference-in.html

With the fuse panel completed it was now on to the daunting task of restoring our wiring harness. In most instances the fastest and easiest route would be to buy a replacement harness however, in our case, certain nice original details of our harness allowed us to justify the massive extra work involved in restoring rather than replacing:

- Our original harness was still supple and the plastic on the wires had not dried out with time

- Despite 3 colour changes over the decades our harness had no paint overspray on it which is almost impossible to properly remove.

- The original harness has markings in Italian on them denoting the task of the individual wires. This in addition to wire colours that are not replicated with the reproduction harness' made keeping the original an easier decision.

- Reproduction wiring harnesses have different wire ends to original making them an immediate giveaway to the knowledgeable observer

With the decision to restore the process all started with getting the old and dirty wiring harness out of storage.

The next step was to lay everything out on a LONG table where the entire harness would be compared to period photos and the original wiring diagrams to ensure that everything is correct. Despite the few circuits involved this job took many days of concentrated effort to get right.

By this stage the harness has most of its cables identified. Once this is done each cable is tested for continuity and resistance to make sure that there are no unexpected problems. Inevitably a few bad wires are found and they are carefully removed whole and replaced. Where we got very lucky is that all of the bad wires were easy to replace colours rather than some of the more strange striped wires that the harness has for some of its circuits.

With the harness all mapped out the next step is full on restoration which we will cover in our next post. Stay tuned.

Thursday, May 15, 2014

The Lone Stallion: Installing the factory ID plate

Way back at the beginning of this blog we showed how the original chassis number was unearthed hidden under layers of paint. Here is the link for those who do not remember the post:

http://dino246blog.blogspot.ca/2010/10/unearthing-identity.html

Back in the day the Dino was seen as a poor mans Ferrari so it was common for owners and even dealers to fit Ferrari badges and horses all over the body and interior. As Dino's have begun to be appreciated as their own sub-brand, restorers have shed the non-original badges leaving only the factory installed Dino markings.

That said there is one Ferrari horse that is totally correct to original and the only Ferrari emblem that appears on the whole car. This is located on a small aluminum plate that is pop riveted to the panel that separates the engine bay from the trunk. Ours was totally original and in excellent condition so it got little more than a quick wipe with a cloth before installing it on the freshly restored panel.

This job was left to Paul and Dad who appear to be relieved to have had such a simple job go smoothly. If only all the tasks could be this easy.

http://dino246blog.blogspot.ca/2010/10/unearthing-identity.html

Back in the day the Dino was seen as a poor mans Ferrari so it was common for owners and even dealers to fit Ferrari badges and horses all over the body and interior. As Dino's have begun to be appreciated as their own sub-brand, restorers have shed the non-original badges leaving only the factory installed Dino markings.

That said there is one Ferrari horse that is totally correct to original and the only Ferrari emblem that appears on the whole car. This is located on a small aluminum plate that is pop riveted to the panel that separates the engine bay from the trunk. Ours was totally original and in excellent condition so it got little more than a quick wipe with a cloth before installing it on the freshly restored panel.

This job was left to Paul and Dad who appear to be relieved to have had such a simple job go smoothly. If only all the tasks could be this easy.

Monday, May 12, 2014

An incredibly tight fit: Greasing the radiator to help it in

Yes you read that correctly. The fit between the body opening and the radiator was so incredibly tight that we actually had to grease the side of the radiator to help it slide into position. As you can imagine this did not sit too well with Paul who spent hours block sanding the radiator to perfection as chronicled in one of our previous crazy tasks:

http://dino246blog.blogspot.ca/2012/08/crazy-task-5-block-sanding-radiator.html

Luckily the paint on the body and radiator were just the correct number of coats and everything installed without the slightest scuff or mark. Regardless we were amazed that Ferrari would have such incredibly tight tolerances in the radiator fit and then have enormous bolts fixing it in place requiring a rather large 22mm wrench to tighten. It is fair to say you can lift the car from the radiator mounts.

Now the radiator is fitted and all the ancillaries around it are installed. This includes the rad fan motors, rad straps with correct LOBO bolts, correct Serflex hose clamps, and radiator hoses with period markings on them. We are quite pleased with the assembly as everything looks just 'right' in the nose.

http://dino246blog.blogspot.ca/2012/08/crazy-task-5-block-sanding-radiator.html

Luckily the paint on the body and radiator were just the correct number of coats and everything installed without the slightest scuff or mark. Regardless we were amazed that Ferrari would have such incredibly tight tolerances in the radiator fit and then have enormous bolts fixing it in place requiring a rather large 22mm wrench to tighten. It is fair to say you can lift the car from the radiator mounts.

Now the radiator is fitted and all the ancillaries around it are installed. This includes the rad fan motors, rad straps with correct LOBO bolts, correct Serflex hose clamps, and radiator hoses with period markings on them. We are quite pleased with the assembly as everything looks just 'right' in the nose.

Sunday, May 11, 2014

A Mother's Day Story: One of those unforgettable days from my youth

As families around the world celebrate Mother's Day today, I would like to share a story from my youth.

Many years ago when I was about 12 years old (give or take) it was Mother's Day and my Mother asked me to go buy flowers for my Grandmother. At first, like many children, I resisted but with a stern glance I was quickly motivated to my bike where I set off for the market. I remember it to be a beautiful Spring day; sunny and just on the edge of warm.

As I arrived at the market, the parking lot was totally empty bar one car sitting alone in the middle. Like a beam from heaven it was a bright yellow Dino 206GT. At the time I was not hugely knowledgeable about the subtle differences in Dinos but I immediately identified the exposed fuel filler and wood rim steering wheel that made me sure that it was a 206.

Transfixed with rapture I just stood there visually taking in as much as I could knowing that this encounter would serve as inspirational fuel for decades to come. After a while of staring a grey haired gentleman appeared almost from nowhere, slipped effortlessly into the drivers seat, awoke the engine, and powered away. To this day I remember that moment like it was yesterday and it is one of my most vivid childhood memories.

With my ocular cup overflowing and the flowers purchased I raced home to tell the tale of my sighting. Needless to say that it was my brother Paul who took the greatest interest and to this day we still talk of that sunny day in May.

Many years ago when I was about 12 years old (give or take) it was Mother's Day and my Mother asked me to go buy flowers for my Grandmother. At first, like many children, I resisted but with a stern glance I was quickly motivated to my bike where I set off for the market. I remember it to be a beautiful Spring day; sunny and just on the edge of warm.

As I arrived at the market, the parking lot was totally empty bar one car sitting alone in the middle. Like a beam from heaven it was a bright yellow Dino 206GT. At the time I was not hugely knowledgeable about the subtle differences in Dinos but I immediately identified the exposed fuel filler and wood rim steering wheel that made me sure that it was a 206.

Transfixed with rapture I just stood there visually taking in as much as I could knowing that this encounter would serve as inspirational fuel for decades to come. After a while of staring a grey haired gentleman appeared almost from nowhere, slipped effortlessly into the drivers seat, awoke the engine, and powered away. To this day I remember that moment like it was yesterday and it is one of my most vivid childhood memories.

With my ocular cup overflowing and the flowers purchased I raced home to tell the tale of my sighting. Needless to say that it was my brother Paul who took the greatest interest and to this day we still talk of that sunny day in May.

Saturday, May 3, 2014

Reducing Rattles: Installing custom foam in the floor cavity

From the start it has always been our intention to drive the Dino when it was finished. As such we have employed processes and materials that offer greater durability and function than original provided that they be installed in a manner that is not visible from the outside. This practice is commonplace in the best Pebble Beach winning restorations and we were happy to incorporate them on our project.

In this post we will look at one of these upgrades. From factory the Dino floor was made up of two thin fiberglass sheets pop riveted to the chassis. One sheet makes up the inner floor while the other makes up the lower floor that is seen when looking under the car. Between them is open space which turns the whole area into a drum. To make matters worse, at Scaglietti, the floor is installed before the chassis is painted (meaning the tubes are bare steel) and the floor is not sealed in any way to keep rain water out.

For these reasons the Dino chassis is prone to terrible rust as the tubes can spend years in a bath of un-evacuated rain water. In our case the floors had never been removed and we were lucky to find limited rust when the car was disassembled. Once the car was painted the chassis was treated with an anti-rust primer and then painted with an epoxy paint offering much more rust resistance than bare steel.

With the chassis members protected it was time to turn our attention to the hollow space in the floor. Again with the car being a driver we wanted the floor to be more solid and offer less transmission of road heat and noise. To this end we investigated different foam materials and ran into sizing problems where no material was the correct thickness. Eventually we found a company that cut some closed-cell foam to our specification creating for us a sheet that was just over 1mm thicker than the gap between the floor panels. Closed-cell foam was used because it will not absorb water and the extra millimeter of thickness ensures a tight press fit without bulging the fiberglass floor.

With the foam purchased the next step was to make cardboard patterns from which to cut the pieces. Once all the patterns were made it was off to the large sheet to determine a layout that gave us the best yield (the material was expensive and we did not want to waste any).

Below is an image of all the foam pieces in place before the floor is installed. Between the painted chassis and the closed-cell foam the chances of rust are much reduced from before. To seal things even better, a thin coating of seam sealer was placed between the chassis tubes and the fiberglass floor being extra careful to not have any visible sealer on the outside thereby maintaining the most original look possible.

Lastly with the floor in place the new rocker panels had to be drilled for the mounting rivets. We determined that originally these rivets were placed very close to exactly 10cm apart so we laid out a string to ensure a straight line and made holes in the correct location staying faithful to the original spacing. To top things off we installed black powder coated rivets for a nice clean install that looks factory original but is much more durable than it ever was.

One thing to note is that the fitting of foam to the underside of the chassis is very much a marginal improvement in sound transmission to having the area hollow. Many people think that installing something like this makes the car Mercedes quiet inside and nothing would be further from the truth. The reality is that the inside of a Dino is a loud place to be regardless of what you do and the foam is used to dull some of the annoying rattles and frequencies that more cheapen the sound rather than take away from the original character of the car.

Subscribe to:

Posts (Atom)